Rhino Track Drive Module

$499.00

The Rhino Track Drive is a tank track module utilizing a two inch wide timing belt tread. Four robust molded pulleys direct the path of a belt, driven by an optional AndyMark gearbox or transmissio...Read More

Product Overview

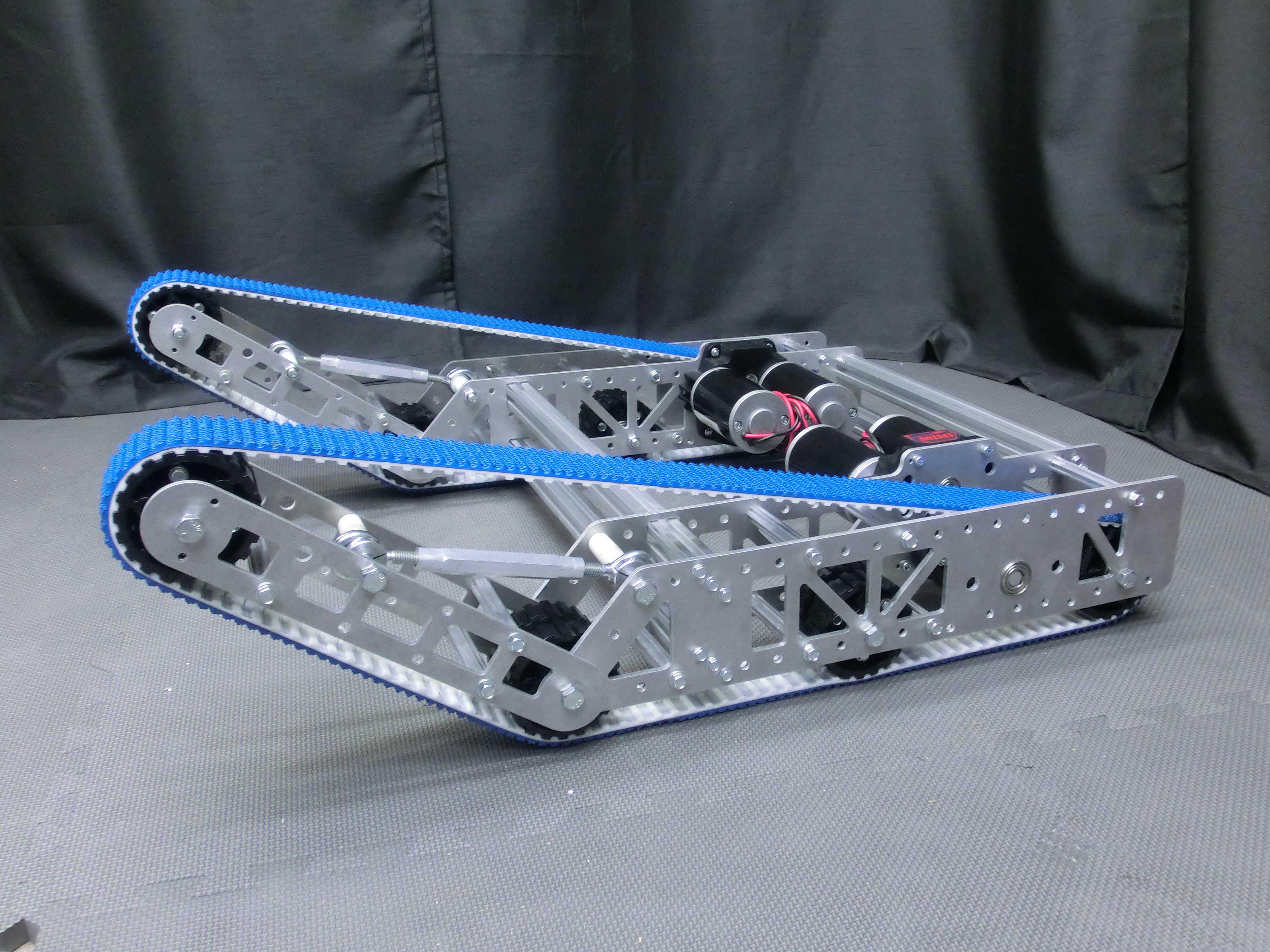

The Rhino Track Drive is a tank track module utilizing a two inch wide timing belt tread. Four robust molded pulleys direct the path of a belt, driven by an optional AndyMark gearbox or transmission. Two of these modules can be used to create a tank drive-base. The Rhino Track Drive features rigid, 3/16 inch thick aluminum plates and an easily adjustable belt tension mechanism. This is an ambidextrous module, so it can be used for the left or right side just by switching the plates from one side to the other. The Rhino Track Drive Module ships in an un-assembled kit. Please see the assembly instructions for assembly assistance.

This module includes one belt. In order to create a typical drive system for most applications, two modules will need to be purchased. We suggest the use of four (4) pieces of 1 in. wide extrusion as bracing structure between two Rhino Track Drive Modules. Pictures of this setup version are shown below.

During normal use of the Blue Nitrile Tread, the blue rubber may begin to delaminate (split apart from the timing belt). If this happens, please follow these steps to fix the belt:

- Keep the belt mounted to the drive pulley mechanism (do not remove the belt from your robot)

- Clean both surfaces where the delamination is happening, removing debris and dirt

- Take time to allow the cleaned area to dry

- Use a rubber to rubber adhesive such as super glue. This has great bonding properties to adhere the tread to the urethane timing belt material.

- Keep pressure on the newly glued area by moving this area over an end pulley. This applies continual contact between the rubber and timing belt.

- Wait 20-30 minutes for the adhesive to cure.

Not Included:

- A gearbox, such as the Toughbox Mini, as shown in the layout print and example pictures.

- Bumper brackets are also not included.

Belt Tension:

- Proper belt tension is detailed in this document.

Included Items:

- 1 - 250 Sprocket and Pulley Spacer (am-0207a)

- 8 - 3/8 in. Round Shielded Bearing (1614ZZ) (am-0209)

- 4 - 985x375 Spacer (am-0441)

- 6 - 10-32 Nylock Nut (am-1042)

- 6 - 10-32 x 1.25 in. Button Head Cap Screw (am-1260)

- 6 - 3/8-16 x 4.25" Hex Head Bolt Grade 5 (am-1297)

- 6 - 3/8 in. x 1/16 in. Washer (am-1393)

- 6 - 3/8-16 Nylock Jam Nut (am-1394)

- 2 - Aluminum Spacer 0.75 x 0.382 x 0.625 in. (am-1451)

- 1 - 0.5 in. Hex HD Collar Clamp (am-1526)

- 20 - 1/4-20 x 0.75 in. Slotted Indented Hex Thread Cutting Screw (am-1591)

- 4 - Pulley, Timing 42 tooth, HTD profile, 15mm wide, polycarbonate (am-2234)

- 2 - Collar Clamp, 3/8" Bore, Aluminum (am-2382)

- 1 - 500EX Hex Hub (am-2568)

- 10 - Churro Aluminum Tube 3.375" +/- 0.125" Long (am-2569)

- 1 - 85 Tooth 5 mm 15 mm Wide Timing Gates Belt (am-2703)

- 1 - 1/2 in. Hex Shielded Flanged Bearing (FR8ZZ-HexHD) (am-2986)

- 8 - 20T Track Drive Pulley (am-3298a)

- 1 - Rhino Track Drive Outside Plate (am-3318)

- 1 - Rhino Track Drive Inside Plate (am-3319)

- 2 - Tank Tread Upper Bar Plate (am-3320)

- 1 - Tank Tread Turnbuckle (am-3321)

- 1 - 85 Tooth 5 mm 15 mm Wide Timing Belt (am-3661)

- 2 - 0.375 in. Hex Molded Spacer 0.063 in. Long (am-3947-063)

- 2 - 0.375 in. Hex Molded Spacer 0.188 in. Long (am-3947-188)

Included with am-3322

- 1 - Blue Roughtop Nitrile Track Timing Belt (am-3288)

Included with am-5514

- 1 - Black Flat Urethane Track Timing Belt Tread (am-4017)

-------------------------------------------------------------------------------------

Example photos of a drive system made with two Rhino Track Drive Modules:

Specifications

- Material: Carbox Nitrile Rubber or Black Urethane

- Overall Length: 30.44 in. with Upper Arm at 34 degree angle, (31.3 in. with Upper Arm at 5 degrees and moved in to secondary pivot point)

- Weight: 8.9 lbs (no gearbox, no motors)

- Width: 3.75 in.

Documents

Returns

Returns are accepted within 30 days of purchase.

View our return policy here.

Recommendations

7 reviews

-

Nice product, but no delivery to pit

Hi there. So glad you were able to bring our product to the championship. However for some reason it did not get delivered to our pit, we had to track it down. It was found, but there was a "gap" in your system. All's well that ends well.

-

"It's now a proven product"

"I'm a mentor on team 4550. We decided to go with the Rhino drive the first week of build season. At that time there were a lot of FEAR (False Evidence Appearing Real) in the FIRST community about using these new modules. There were concerns about durability and robustness just to mention a few. Now after competing in two regionals and the Championship the Rhino drive has proven it excels in these two areas and more. This years' game used and abused the modules. In addition we played defense most of the time and were in many pushing contest. In 30 plus matches during the season we never had a drive failure or had to replace a drive belt. You ought to consider renaming the modules to 'Timex'. They "take a licking and keep on ticking". You can bet we'll be looking at using these modules again in years to come."

-

Rhino

The directions leave something to be desired especially when a high school robotics team with little mechanical knowledge is trying to learn how to put things together.

-

Very Disappointed Defective Parts Were Shipped

We have emailed to get new pulleys, but I am very disappointed AM knew of the issue and not only didn't notify the customers who purchased them to let them know of the issue and the fix, but continued to send out defective replacements when ordered. We are really feeling that AM has left us to fail since we have not heard back on the timing of replacement pulleys and we are heading into bag & tag. Our worst case is we will be at competition changing out pulleys instead of using the time for practice matches. (AndyMark response: We disagree with the assessment of this customer review, and we stand by our customer service. Here is a timeline of the events: Feb. 8th: We found out about this issue, started to investigate the problem and change the mold. We began responding to customers input on this issue, and did so each day after. Feb. 8th: We posted our response to a public discussion board and on our product website. Feb. 10th: We posted the improvements which were going to be made to the new version of the pulley (and mold tool). We also updated the public discussion board and our product website. Feb. 10th: We determined that many of the original pulleys were good, as we were not able to consistently recreate the cracks and breaks Feb. 11th: Our mold changes were complete, and we began testing the new pulley. Feb. 15th: We began sending out new versions (Rev4) of the pulley replacements to customers who requested them. Rev3 pulleys were quarantined. Feb. 17th: We reached out to all of the customers who have received the original pulleys who have not contacted us yet, offering them replacements for broken pulleys and a limited amount of spares if they did not have broken pulleys. Feb. 17th: We receive this negative review for not being responsive enough, although we agreed to send out all of the replacement pulleys they wish to have.)

-

out of stock

every time I get a notice that the Rhino tracks are available and go to purchase. They are always out of stock. (AndyMark Response: We apologize for the frustrations this causes. We do apologize for high demand items in and out of stock quickly. As a supplier it is difficult for us to anticipate customer demand, maintain adequate inventory to meet that demand, and ensure product prices are competitive. However, we're always looking for ways to improve this.)

-

Review

Good but Andymark needs to improve their shipment schedule (or just plan ahead a bit more)

-

Rhino Track Drive Module (am-3322)

Excellent